Vertical Openwell Submersible Pump to Serve Your Applications

Vertical Openwell Submersible pump sets are suited for open wells or tanks with large fluctuations in water level.

This job is done underwater and at the bottom of the well. Vertical pumps extract fluids from a deep tank or well. They vary in a variety of forms, sizes, and uses, but they always feature a characteristic vertical structure that pushes liquids upward via a pipe in a vertical orientation.

You can use these pumps in a wide variety of operating temperatures, pressures, and liquids ranging from common water to caustic, combustible, and even difficult-to-process liquids and chemicals.

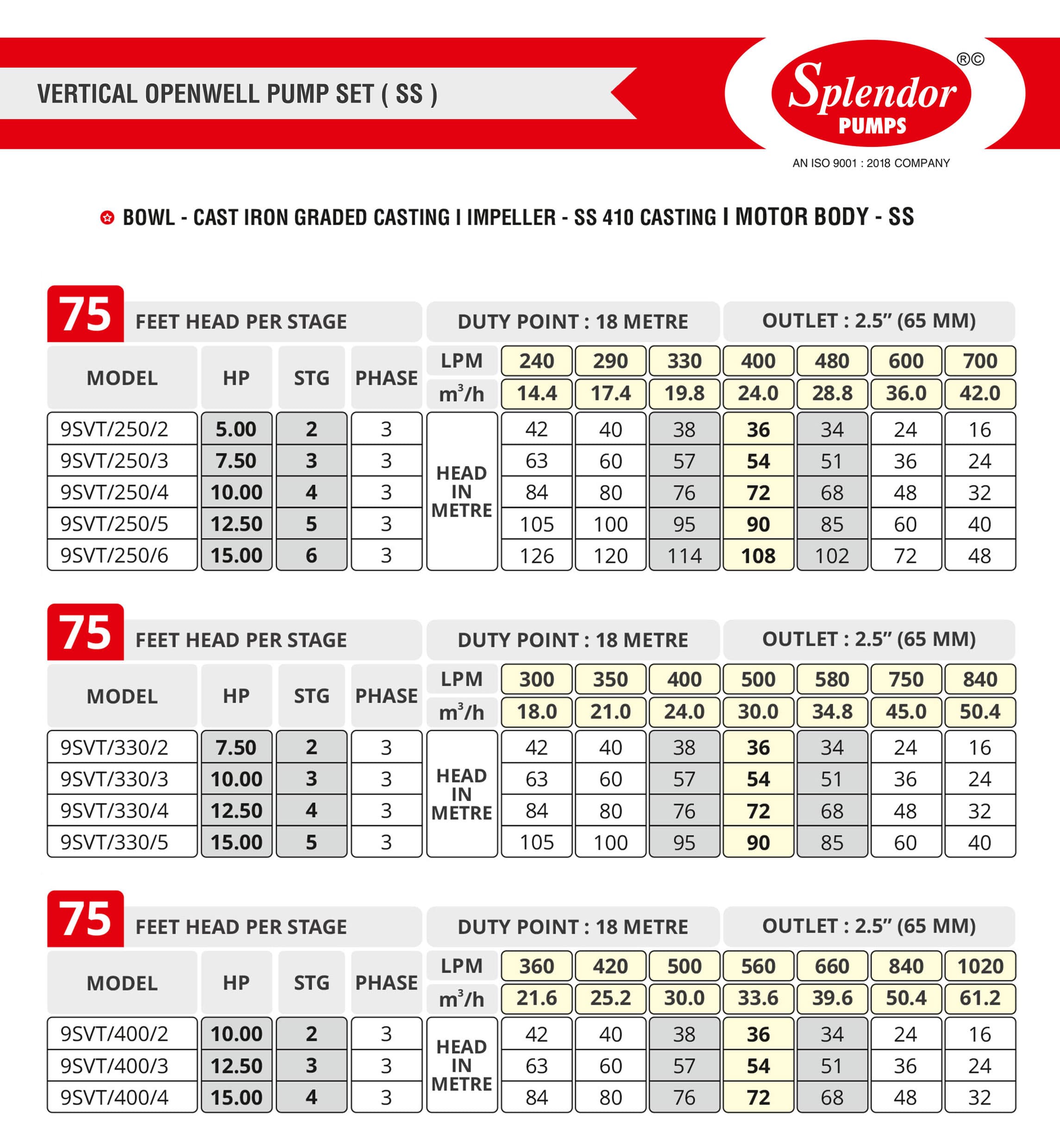

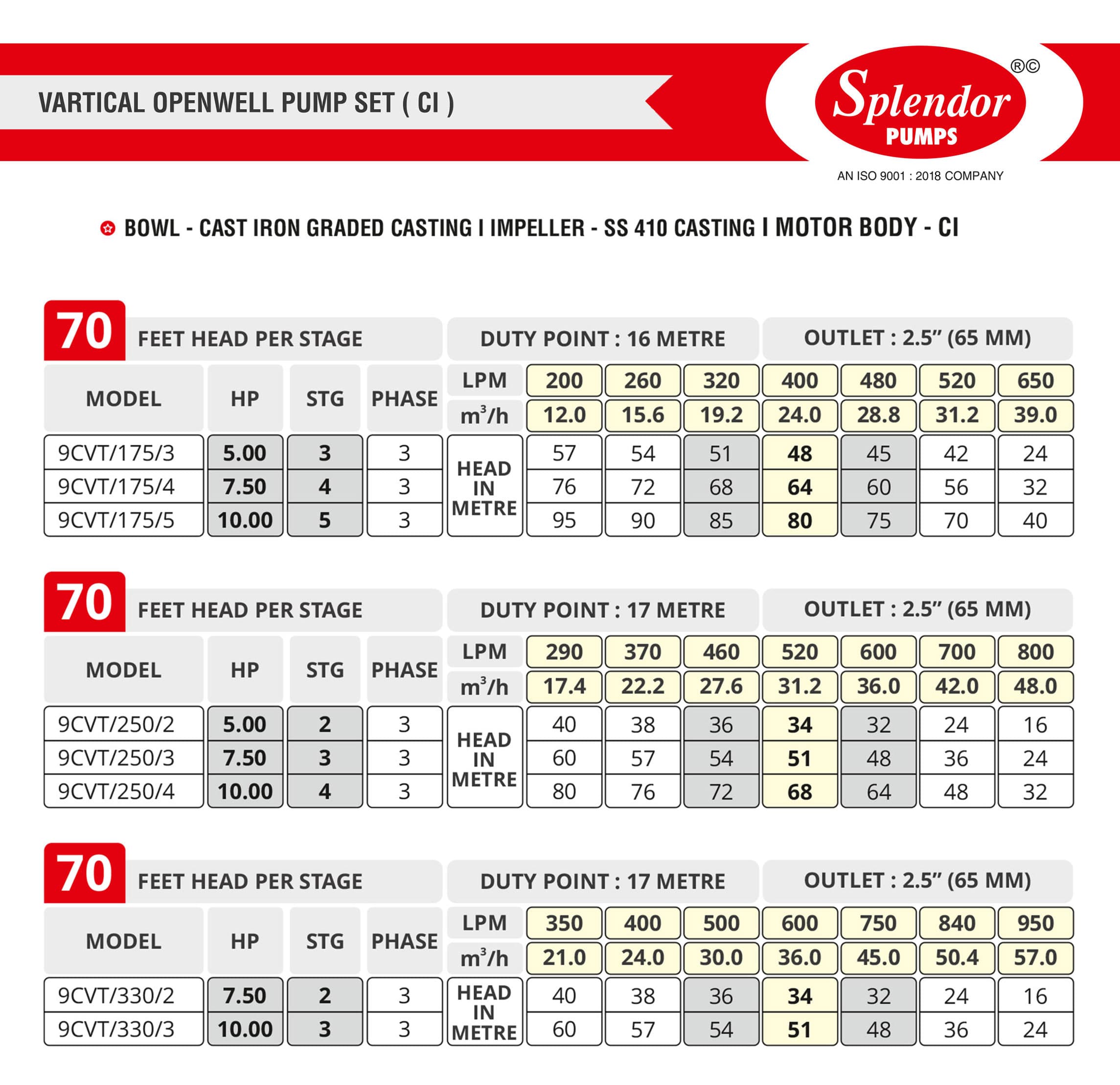

Various Models Of Vertical Openwell Sub. Pump

Splendor Pumps commenced operations in 1996, the company is embarked on a mission to produce quality risk, cost-efficient, reliable and durable Submersible Pumps & Cable for both Indian and overseas markets

PumpBuy from the Top Pump Brands

Higher Operating Efficiencies

These pump sets provide higher operating efficiencies that result in a high water discharge rate. Splendor Pump LLP is one of the well-known Vertical Openwell Submersible Pump Manufacturers in India, providing world-class pumping solutions that are technically innovative, extremely energy efficient, and long-lasting.

As one of the leading Vertical Openwell Submersible Pump Suppliers in India, we are dedicated to providing outstanding pumping solutions across various industry verticals. Our goal is to help industries by providing them with excellent pump sets and solutions that are of top-notch quality yet affordable.

We want to create, manufacture, and distribute the greatest and most creative submersible pumps in the market categories in which we operate. Also, we aim to maintain our position as the premium brand that offers the highest value and return on investment.

FeaturesTechnical Details

Higher Operating Efficiencies

Product Features

- Optimized hydraulic design for efficient performance.

- Rotor are grinding & burnished to give better surface finish value which ensure long life.

- Heavy duty, water- lubricated bearing for long trouble free operation.

- Specially designed thrust bearing to with stand high axial load.

- Sleeve and thrust bearing designed for longer life.

- High operating efficiency & more durability and hygiene.

- Dynamically balanced rotating parts to ensure minimum vibration and longer life.

- Designed for wide voltage applications.

- Starts easily at low voltage, easy installation and low maintenance.

| TECHNICAL SPECIFICATIONS | ||

|---|---|---|

| 1 | KW / HP RANGE | 3.70/5.00 TO 11.00 / 15.00 |

| 2 | VOLTAGE RANGE | 380 TO 440 VOLT ( THREE PHASE ) |

| 3 | DISCHARGE LPM | UP TO 1500 LITRE |

| 4 | HEAD | UP TO 125 METRE |

| 5 | DELIVERY | Upto 75 MM |

| Pump Material | ||

|---|---|---|

| 1 | DIFFUSER | CAST IRON |

| 2 | IMPELLER | SS – 410 |

| 3 | CASTING PART | Cast iron FG 200 Grade |

| 4 | BUSH | GM LTB- 4 / NBR |

| 5 | PUMP SHAFT | SS – 410 |

| 6 | SLEEVE AND COUPLING | SS – 410 |

| Motor Material | ||

|---|---|---|

| 1 | MOTOR BODY | SS – J4/ CAST IRON |

| 2 | MOTOR SHAFT | SS – 420 |

| 3 | CASTING PART | CAST IRON FG 200 GRADE |

| 4 | BUSH | CARBON / GM LTB – 4 |

| 5 | THRUST BEARING | CARBON V/S SS |

| 6 | STAMPING | SILICON STEEL |

| 7 | ROTOR | COPPER / ALU. PRESSURE DIE – CAST |

| 8 | WINDING | MULTI LAYER PVC INSULATED WIRE |

TechnicalSpecifications

Higher Operating Efficiencies

An ISO 9001:2018 Company

An ISO 9001:2018 Company

An Agricultural Pump Industry Since 1997

ApplicationApplication Area Where We Serve

Higher Operating Efficiencies

AGRICULTURE

AGRICULTURE

DOMESTIC

DOMESTIC

INDUSTRY

INDUSTRY

HOSPITAL

HOSPITAL

GARDEN

GARDEN

Sailent Features

Sailent Features  Pump Material

Pump Material  Motor Material

Motor Material